-

Wyślij do nas e-mail

sale@lscmagnetics.com -

Numer kontaktowy

+86 -13559234186

Wyślij do nas e-mail

sale@lscmagnetics.com

Numer kontaktowy

+86 -13559234186

Sukces lub porażka projektu z prefabrykatów betonowych zależy od szczegółów fazowania! Jak dokonać idealnego wyboru dla swojego projektu?

Sep 05, 2025W świecie prefabrykatów betonowych fazowanie, pozornie nieistotny szczegół, ma daleko idący wpływ na estetykę, funkcjonalność i bezpieczeństwo elementu. Dobrze zaprojektowane i wykonane fazowanie nie tylko poprawia walory wizualne produktu, ale także znacząco poprawia jego trwałość i wydajność. Wbudowane fazowania Są kluczowym elementem tego procesu. Dzieje się tak, ponieważ osadzone fazki to coś więcej niż tylko proste akcesorium lub usprawnienie procesu. Są kluczowym symbolem przejścia branży prefabrykatów betonowych od „produkcji ekstensywnej” do „precyzyjnego wytwarzania”.

Najpierw wyjaśnijmy kluczową rolę, jaką odgrywają fazowania w przemyśle prefabrykatów:

1. Zapobieganie koncentracji naprężeń i poprawa trwałości konstrukcji: Krawędzie betonowe są podatne na koncentrację naprężeń pod wpływem naprężeń, co prowadzi do pęknięć lub uszkodzeń. Fazowanie, poprzez przekształcenie kąta prostego w fazę, skutecznie rozkłada naprężenia i zwiększa odporność na uderzenia. Jest to szczególnie przydatne w przypadku elementów w obszarach o dużym natężeniu ruchu lub narażonych na obciążenia.

2. Ochrona krawędzi i redukcja odprysków i pęknięć naroży: Elementy prefabrykowane są podatne na uszkodzenia spowodowane ostrymi krawędziami podczas produkcji, transportu i montażu. Prawidłowe fazowanie lub zaokrąglanie może znacznie zmniejszyć ryzyko odprysków i pęknięć naroży, redukując koszty i czas naprawy.

3. Ułatwienie wyjmowania z formy i poprawa wydajności produkcji: W projektowaniu form, fazowanie przejść między krawędziami elementów ułatwia wyjmowanie z formy i chroni gotowy produkt. Zmniejsza to opór podczas wyjmowania z formy, zapobiega przywieraniu elementu do formy lub jej uszkodzeniu oraz zapewnia płynniejszy proces produkcji.

4. Poprawa estetyki i faktury: Szczegółowe fazowanie przełamuje monotonię powierzchni betonu, tworząc eleganckie efekty światła i cienia pod wpływem światła, zwiększając wyrafinowanie i ogólną fakturę elementu oraz spełniając estetyczne wymagania elewacji budynku.

5. Lepsza wodoodporność: W obszarach takich jak ściany piwnic, fazowanie w połączeniu z nieprzepuszczalnym betonem może zoptymalizować właściwości betonu w zakresie wodoodporności i ochrony przed wilgocią, zmniejszając ryzyko przecieków.

Wbudowane fazowania odgrywają istotną rolę w przemyśle prefabrykacji. Jakie są ich główne rodzaje?

| Typy | Główne materiały | Główne cechy | Typowe scenariusze zastosowań |

| Zatopione w PCV fazki | Plastik PCV | Lekkie, ekonomiczne, odporne na korozję, łatwe do formowania, odpowiednie do różnych kątów i rozmiarów | Elementy ogólne, takie jak panele ścienne wewnętrzne i zewnętrzne, panele kompozytowe itp. |

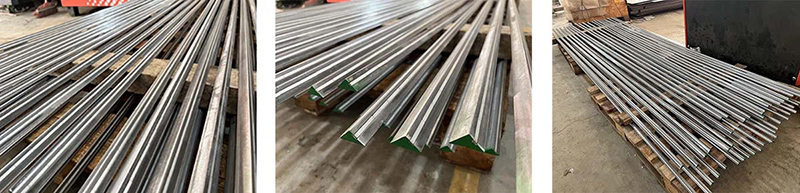

| Metalowe fazki osadzone | Stal nierdzewna, stal ocynkowana | Wysoka wytrzymałość, odporność na zużycie, dobra trwałość, wyraźne i ostre linie fazowania | Ciężkie elementy, obszary o wysokiej częstotliwości użytkowania i zwykły beton |

| Zatopione w gumie/elastomerze skosy | Kauczuk syntetyczny, poliuretan | Wysoka elastyczność, doskonałe właściwości wyjmowania z formy, możliwość ponownego użycia, zmniejszone odpryskiwanie | Złożone kształty, elementy o nietypowym kształcie, elementy trudne do wyjęcia z formy |

| Kompozytowe zatopione sfazowania z pianki | Polistyren (EPS) | Lekki, trwale osadzony w elemencie, prosta konstrukcja, niski koszt | Rowki prowadzące do kontroli pęknięć, zastępujące tylne szczeliny |

| Degradowalne, osadzone fazowania | Specjalny papier lub włókno | Po połączeniu z betonem następuje jego zestalenie, a po utwardzeniu można go zdegradować i usunąć, tworząc jednolitą fazę | Elementy wymagające specjalnych procesów produkcyjnych lub szczególnych wymagań dotyczących powierzchni fazowanych |

🔍 Rozważania dotyczące wyboru

Wybierając odpowiedni typ fazowania dla swojego projektu, należy kompleksowo rozważyć następujące czynniki:

Funkcja komponentu i wymagania projektowe: Czy najważniejsze są wytrzymałość konstrukcyjna i estetyka (np. goły beton), czy tylko ochrona krawędzi? W przypadku ciężkich komponentów lub obszarów narażonych na uderzenia należy wybrać mocniejszą listwę fazującą.

Właściwości betonu: Płynność i skurcz betonu mogą wpływać na jakość fazowanego kształtu. Beton o słabej płynności wymaga listwy fazującej, która skutecznie wytrzymuje nacisk i zapobiega odkształceniom.

Proces produkcji i wyjmowanie z formy: Linie produkcyjne wymagające szybkiego wyjmowania z formy mogą preferować paski fazujące o wysokiej elastyczności, aby zmniejszyć opór. Konstrukcja formy (np. do przodu lub do tyłu) również wpływa na wybór paska fazującego i metodę mocowania.

Narażenie na czynniki środowiskowe: Czy element będzie narażony na działanie środowiska korozyjnego, cykliczne suszenie na mokro lub zamrażanie i rozmrażanie? Czynniki te determinują wymagania dotyczące trwałości materiału.

Koszt i skala projektu: Duże projekty mogą obniżyć koszty formowania niestandardowych listew fazujących. W przypadku mniejszych projektów lub projektów o ograniczonym koszcie, standardowe listwy PVC są bardziej ekonomiczne.

⚠️ Wskazówki budowlane

W przypadku stosowania wstępnie zakopanych fazowań, podczas budowy należy zwrócić uwagę na następujące kwestie:

Precyzyjne pozycjonowanie i bezpieczne mocowanie: Podczas montażu wymagane jest precyzyjne pozycjonowanie, aby zapobiec przesuwaniu się lub unoszeniu się elementów podczas zalewania i wibracji. Zazwyczaj mocuje się je za pomocą szczelin, kołków ustalających lub specjalnych zacisków na formie.

Zapewnij kompatybilność i uszczelnienie: Sprawdź, czy materiał fazowania jest kompatybilny z dodatkami do betonu (takimi jak rozcieńczalniki). Podczas montażu upewnij się, że połączenia z formą są uszczelnione, aby zapobiec przeciekom i wpłynąć na przejrzystość fazowania.

Prawidłowe wylewanie i wibrowanie: Ostrożnie wibruj obszar wokół fazy, aby upewnić się, że beton jest gęsty i pozbawiony pustych przestrzeni. Uważaj jednak, aby nie wibrować fazy zbyt mocno, ponieważ może to spowodować jej uszkodzenie lub przesunięcie.