-

Wyślij do nas e-mail

sale@lscmagnetics.com -

Numer kontaktowy

+86 -13559234186

Wyślij do nas e-mail

sale@lscmagnetics.com

Numer kontaktowy

+86 -13559234186

W jaki sposób magnesy zapewniają bezpieczeństwo i jakość w przetwórstwie żywności?

Sep 18, 2025W codziennym przetwórstwie żywności często pomijamy niedoceniany „ochronnik” magnesów. Występują one w różnych formach na całej linii produkcyjnej, dyskretnie chroniąc bezpieczeństwo i jakość żywności od momentu, gdy surowce trafiają do fabryki, aż do momentu, gdy gotowy produkt opuszcza fabrykę. Jak te pozornie proste urządzenia magnetyczne stają się tak istotnym i kluczowym elementem procesu przetwórstwa żywności? Przyjrzyjmy się ważnej roli technologii magnetycznej we współczesnym przemyśle spożywczym.

Skąd bierze się zanieczyszczenie żywności metalami?

- Zanieczyszczenia surowców: Fragmenty metalu mogą przedostać się do upraw w trakcie procesu sadzenia i zbioru.

- Zużycie sprzętu: cząstki metalu powstające w wyniku zużycia maszyn przetwórczych w trakcie ich pracy.

- Czynnik ludzki: Przedmioty metalowe (np. guziki i biżuteria) przypadkowo upuszczone przez pracowników.

- Konserwacja: Małe części, takie jak śruby i nakrętki, które mogą zostać pozostawione podczas napraw i konserwacji.

Zanieczyszczenia te obejmują zarówno śruby o wielkości 50 mm, jak i zanieczyszczenia o wielkości zaledwie 30 µm, które mogą przebić opakowania, spowodować skaleczenia u konsumentów lub uszkodzić drogi sprzęt.

Technologia separacji magnetycznej: Nieopiewany bohater przemysłu spożywczego

Technologia separacji magnetycznej wykorzystuje siły magnetyczne o wysokiej intensywności, aby skutecznie usuwać żelazo i inne metale magnetyczne z surowców spożywczych i procesów produkcyjnych. Typowe urządzenia do separacji magnetycznej obejmują:

- Pręty magnetyczne:Zainstalowane w portach zasilających i rurach transportowych w celu wychwytywania opiłków żelaza

- Ekrany magnetyczne:Służy do filtrowania zanieczyszczeń metalicznych z cieczy i szlamów

- Separatory magnetyczne do szuflad:Usuwa drobne zanieczyszczenia metalowe z sypkich produktów suchych

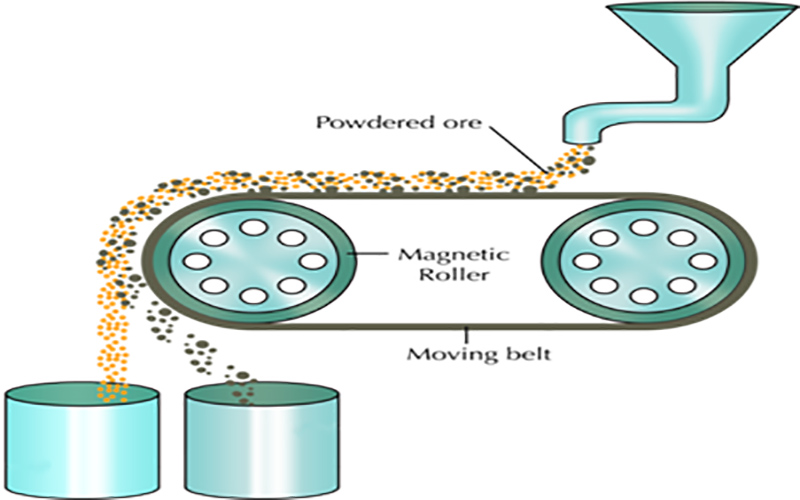

- Separatory magnetyczne:Służy do przesiewania i usuwania żelaza z proszków poddanych recyklingowi

Zastosowania technologii magnetycznej w różnych gałęziach przemysłu spożywczego

1. Przetwarzanie zboża

Podczas przetwarzania zbóż, takich jak ryż, mąka czy mąka kukurydziana, na wlotach urządzeń czyszczących surowce, młynów i maszyn pakujących instalowane są silne pręty magnetyczne, aby skutecznie usuwać zanieczyszczenia żelazne z surowców.

Pozwala to nie tylko zachować kolor i smak produktu, ale także wydłuża żywotność sprzętu. Na przykład, po zainstalowaniu silnych prętów magnetycznych w swojej linii produkcyjnej, duża firma przetwórstwa ryżu zmniejszyła ilość ciał obcych w swoim produkcie o 98%.

2. Produkcja oleju jadalnego

W produkcji oleju jadalnego silne pręty magnetyczne odgrywają rolę w całym procesie – od tłoczenia oleju po rafinację:

- W trakcie procesu tłoczenia zapobiegają przedostawaniu się zanieczyszczeń żelaznych do urządzeń tłoczących olej.

- W trakcie procesu rafinacji dodatkowo absorbują zanieczyszczenia żelazem z ropy naftowej.

3. Piekarnictwo i cukiernictwo

W przemyśle piekarniczym i cukierniczym separatory magnetyczne służą do kontroli wszystkich przyjmowanych składników suchych (takich jak mąka i cukier) oraz płynnych (takich jak aromaty, przyprawy i oleje).

Na przykład firma Colonial Cookies of Canada zainstalowała w swojej linii produkcyjnej separatory magnetyczne Pneumag i liczne filtry cieczy, aby chronić proces wytwarzania ciastek przed zanieczyszczeniem metalami.

4. Produkcja dodatków do żywności

Czystość dodatków do żywności ma bezpośredni wpływ na jakość i bezpieczeństwo żywności. Silne pręty magnetyczne zapewniają czystość surowców dodawanych do żywności i zapobiegają wpływowi zanieczyszczeń żelazem na działanie dodatków do żywności.

Technologia separacji magnetycznej i systemy zarządzania bezpieczeństwem żywności

Technologia separacji magnetycznej jest kluczowym elementem systemu HACCP (Analiza Zagrożeń i Krytyczne Punkty Kontroli). HACCP to uznany na całym świecie system analityczny służący do identyfikacji potencjalnych zagrożeń i wdrażania środków zapobiegawczych w celu ich eliminacji lub ograniczenia.

Solidny system HACCP z wysokiej jakości funkcją separacji i wykrywania metali oferuje wiele korzyści:

- Monitorowanie surowców od dostawców

- Zapobieganie przedostawaniu się zanieczyszczeń metalowych do procesu produkcyjnego

- Szybkie wykrywanie zużycia lub awarii maszyny

- Punkty kontrolne, które redukują nieplanowane konserwacje i przestoje

Obecnie wielu sprzedawców detalicznych przeprowadza audyty systemów zarządzania bezpieczeństwem swoich dostawców pod kątem zgodności z normami międzynarodowymi, takimi jak Rozporządzenie UE 852/2005 i ISO 22000. Skuteczny system separacji magnetycznej może pomóc firmom w spełnieniu tych wymogów regulacyjnych.

Kluczowe zagadnienia dotyczące wyboru i konserwacji urządzeń do separacji magnetycznej

1. Charakterystyka surowca: Wybór sprzętu zależy od wielkości cząstek, zawartości wilgoci i płynności surowca.

2. Proces produkcyjny: produkcja ciągła i wsadowa oraz stopień wymaganej automatyzacji.

3. Ryzyko zanieczyszczenia: Rodzaj i skala potencjalnego zanieczyszczenia metalami.

4. Wymagania dotyczące czyszczenia: łatwość czyszczenia i higieny sprzętu.

Regularna kontrola i konserwacja urządzeń magnetycznych jest również kluczowa. Obejmuje to regularne czyszczenie w celu usunięcia zaadsorbowanych zanieczyszczeń metalicznych, sprawdzanie osłabienia siły magnetycznej oraz zapewnienie prawidłowej instalacji.